The Oji Group implements waste reduction, reuse, and recycling.

We are contributing to the transition to a circular economy and reducing our impact on the environment by minimizing waste generated in the manufacturing process, and by properly treating, recycling, and effectively utilizing waste.

We have set a clear goal of an effective utilization rate of 99% in Japan and 95% or more overseas (final disposal rate of 1% in Japan and 5% or less overseas), we are reducing the amount of final disposal (landfill).

The Group did not commit any regulatory violations and was not subject to any penalties in relation to the storage and management (labeling, sorting, etc.) of waste, proper internal disposal, outsourcing (contracts, manifests), or other aspects of waste handling.

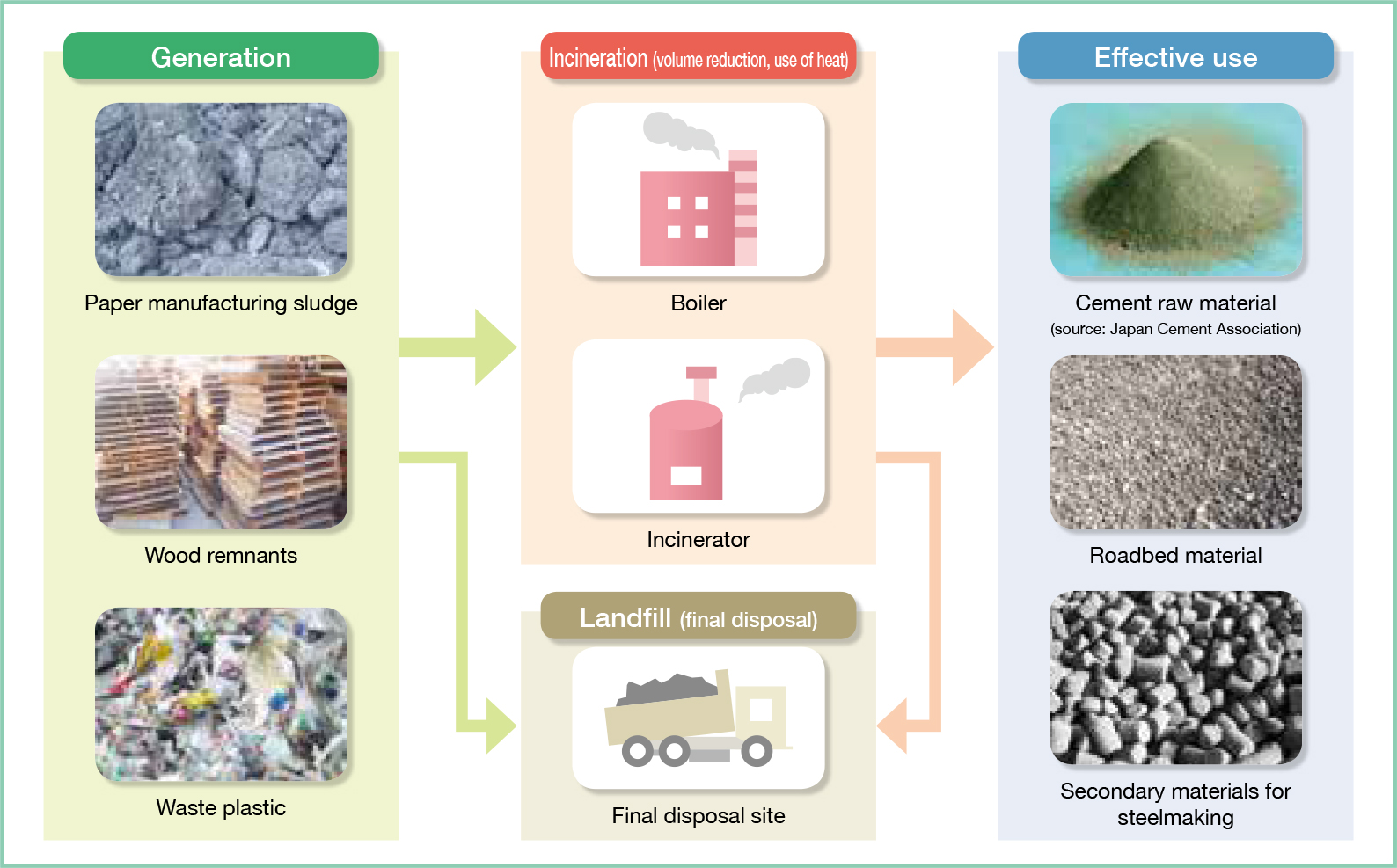

Waste includes paper manufacturing sludge generated in the manufacturing process, wood waste during processing, and ash during fuel combustion. Any wastes are treated to make them harmless and used effectively.

In Japan, ash is used primarily as a raw material in cement and roadbed material. Overseas, paper manufacturing sludge is used as fertilizer and for other applications.

We continuously work to reduce the amount of waste generated and to expand effective utilization.

The effective waste utilization ratio* in FY2023 was 99.0% in Japan and 86.4% overseas.

We will continue to promote the recovery and reuse of raw materials from water used in the manufacturing process and the effective use of combustion ash generated by fuel combustion to obtain electricity and heat used in the production process for roadbed materials, etc., to reduce our environmental impact.

In addition, we participate in the "Environmental Action Plan (Waste Management)" and "Follow-up on the Status of Volatile Organic Compounds (VOC) Emissions Management" of the Japan Paper Association, of which we are a member and are promoting reductions.

In collaboration with other companies, Oji Group operating companies in and around Shizuoka Prefecture have been disposing of wastewater sludge generated at their worksites at final disposal sites (landfills). Still, by incinerating the sludge in the incinerators of paperboard companies licensed to dispose of waste, the paperboard companies obtain heat energy (steam) and reduce the amount of landfill disposal. Paperboard companies are also working to reduce the amount of sludge that must be disposed of in landfills.

In the field of packaging materials, one of the Group's core businesses, we have contributed to the reduction of plastics in society as a whole by approximately 3,000 tons in FY2023 through the replacement of plastic products with renewable eco-friendly paper products.

We expand sales by approximately 5,000 tons by FY2030 and contribute to the transition to a plastic-free society and circular economy.

Within the Oji Group, Oji Nepia is implementing the use of plastic-free packaging materials.

More than 90% of the waste plastic discharged from the Oji Group is derived from plastic mixed with recovered paper, the raw material for paper and paperboard.

Each of our manufacturing bases actively utilizes these materials effectively, and in FY 2023, approximately 98% of them were recycled (including thermal recycling).

We set a target to achieve a 100% recycling rate by FY2030.

As recycling for the future, we reduce the amount of plastic used in society as a whole by promoting the expansion of sales of renewable eco-friendly products, such as the conversion of plastic packaging into paper.

In FY2023, the amount of waste plastic discharged from our group's manufacturing sites was 73,642 tons. Approximately 98%, or 72,419 tons, were recycled (including thermal recycling). The amount of unrecycled waste plastic was 1,215 tons.

Table. Targets, Emissions, Amount Recycled, etc., and Actual Sales of Renewable eco-friendly products for the 10 High Emitters*1 in FY2023

Unit: tonnage in presence, [ ]: total emission ratio

| FY2021 | FY2022 | FY2023 | FY2030 (Target) |

|

|---|---|---|---|---|

| Total amount of waste plastic discharged | 74,426 | 75,684 | 73,642 | |

| (Amount of recycled paper mixed in as raw material) | (67,696) | (68,984) | (68,984) | |

| Amount recycled, etc. | 69,678 [94%] | 73,798 [98%] | 72,419 [98%] | [100%] |

| (of which material and chemical recycling) | (804) | (763) | (282) | |

| Unrecycled amount | 4,749 [6%] | 1,886 [2%] | 1,215 [2%] | [0%] |

| Sales of renewable eco-friendly products | 1,904 | 3,312 | 3,297 | 5,000 or more |

Grand Hotel New Oji, a provider of specified plastic-using products, has set rationalization targets for 12 specified items and is implementing reduction, with the aim of contributing to the preservation and sound development of the living environment.