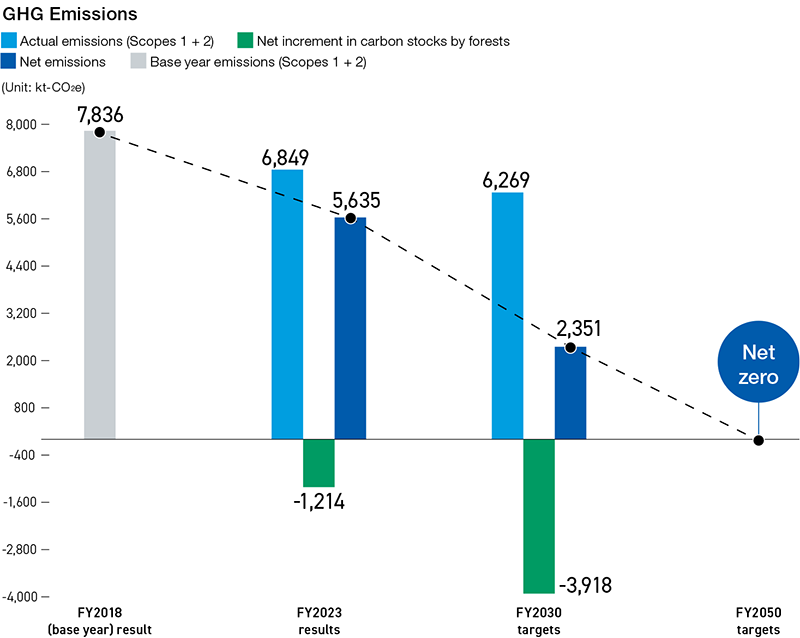

In 2020, the Oji Group formulated its Environmental Vision 2050 centered around the goal of net-zero carbon, while also positioning the Environmental Action Program 2030 as a steppingstone milestone toward achieving its medium-term targets. In a bid to achieve our target of reducing greenhouse gas (GHG) emissions by 70% compared to FY2018 levels, we are working to reduce actual emissions by reducing coal consumption and other emission sources, and increasing the net increment in carbon stocks by forests.

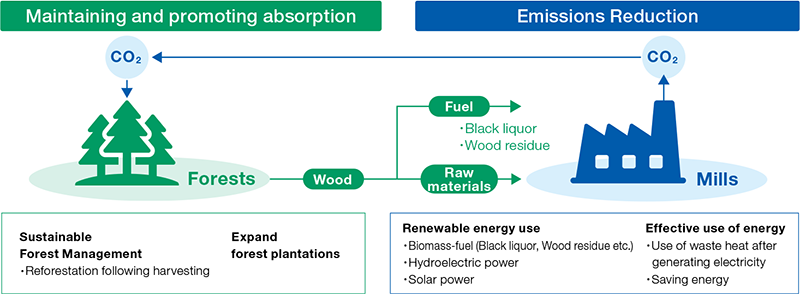

The Oji Group engages in a wide array of business activities, including the manufacture of pulp and paper. In light of the substantial amounts of heat (steam) and electricity consumed, these activities accordingly lead to the emission of GHGs commensurate with this energy use. By working to reduce GHG emissions from energy use and promoting CO2 absorption by forests, we are contributing to climate change mitigation.

Pulp and paper mills generate steam and electricity from black liquor produced in the wood pulp manufacturing process and waste wood unsuitable for use in pulp raw materials. The CO2 emitted during combustion is offset by the CO2 absorbed by trees during growth. In addition, the waste heat (steam) after generating electricity is reused in the manufacturing process in an effort to promote the effective use of energy. Moreover, steps are taken to utilize the electricity generated by the Chitose No. 1 Hydroelectric Power Plant in Hokkaido, a facility that commenced operations in 1910, as well as the solar power systems on factory roofs. Over and above in-house consumption at mills, we also continue to pursue renewable energy generation business using biomass, hydroelectric, and solar power, and are considering wind power generation projects on company-owned sites.

In addition to practicing Sustainable Forest Management through replanting following harvesting, as well as the planting of elite trees with high growth rates, every effort is made to maintain and promote the CO2 absorption functions of forests.

Our target is to reduce net emissions (actual emissions minus the net increment in carbon stocks) by at least 70% compared to FY2018 levels by FY2030. Of this, 20% will be achieved through reductions in actual emissions (total of Scope 1 and Scope 2), and the remaining 50% by increasing the net increment in carbon stocks by forests.

In FY2023, net GHG emissions were reduced by 28.1% compared to FY2018 levels, to 5,635 kt-CO2e.

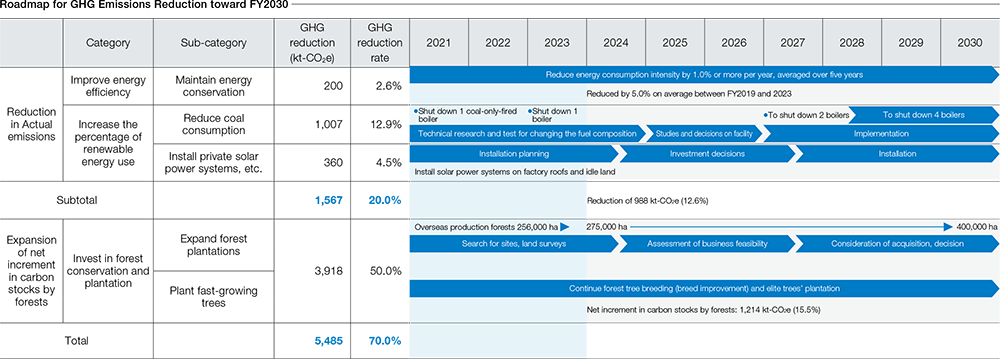

To achieve the FY2030 target, we focus on reducing actual emissions and increasing the net increment in carbon stocks by forests.

Of the 16 boilers in Japan that were burning coal as of FY2018, we will terminate operations at all eight coal-only-fired boilers by FY2030, excluding backup boilers, and switch to gas fuels in a transition phase toward decarbonization. Operations were discontinued at two boilers by FY2023. Plans are in place to discontinue the use of two boilers, one each at the Sobue Mill and Saga Mill of Oji Materia Co., Ltd. by FY2027. We are also considering reducing coal consumption by changing the composition of fuels at coal co-fired boilers.

The gas cogeneration systems planned for installation at the Sobue Mill and Saga Mill, replacing coal-only-fired boilers, will have GHG emissions per unit of output energy lower than the technical screening criterion of 270 g-CO2/kWh set by the EU Taxonomy*.

Further reducing the use of fossil fuels including gas is essential to achieving net-zero carbon emissions from FY2030. To this end, we are considering the use of alternative fuels, including hydrogen, ammonia, and e-methane (synthetic methane).

Moreover, in order to increase the net increment of carbon stocks, we are advancing efforts to acquire overseas forest plantations. Making the most of the tree breeding and forest plantation technologies nurtured over the lengthy period to date, we are engaging in the cultivation of elite fast-growing trees best suited to each region. Moving forward, we are promoting CO2 absorption while expanding forests with a high net increment of carbon stocks.

In conjunction with TOKYO GAS CO., LTD. and Tokyo Gas Engineering Solutions Corporation, we launched a joint study on the manufacture of e-methane at the Oji Paper Tomakomai Mill.

This joint study will examine the domestic production and use of e-methane by investigating the reaction of green hydrogen, produced using electricity from existing hydroelectric facilities and future solar power generation facilities, with CO2 derived from carbon neutral fuel generated and recovered in the pulp manufacturing process.

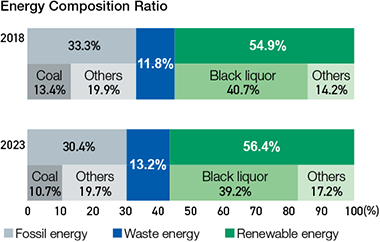

We are working to improve energy efficiency and increase the percentage of renewable energy use to reduce GHG emissions through our business activities. In FY2023, the actual GHG emissions (Scope 1+2) were reduced by 12.6% compared to FY2018 levels, to 6,849 kt-CO2e.

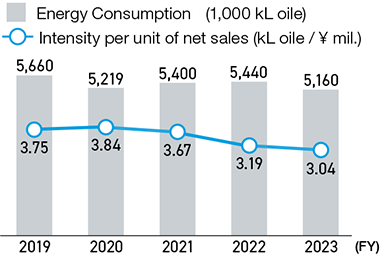

At our mills and plants, the energy management and production departments hold regular energy conservation meetings. They set energy-saving targets, plan equipment upgrades and operational improvements to achieve these targets, and check progress and effectiveness.

KANZAN's Neumühl plant, Walki's Valkeakoski plant, Pietarsaari plant, and Steinfurt plant have obtained third-party certification for the ISO 50001 energy management system.

In FY2023, our major domestic companies made energy conservation investments of ¥0.93 billion, thereby reducing energy consumption by 47 thousand kL (in crude oil equivalent). Across the entire group, energy consumption intensity was reduced by 5.0% per year on the average between FY2019 and FY2023.

Utilizing black liquor, a byproduct of the pulp production process, and other biomass fuels, the Oji Group has increased the percentage of renewable energy use. In an effort to further improve energy efficiency, we are using private hydroelectric power plants while promoting the introduction of solar power generation systems.

In FY2023, the percentage of renewable energy use was 56.4%.

We shut down a coal boiler at each of Oji Materia Nayoro Mill and Oji F-Tex Ebetsu Mill in FY 2021 and FY2023, respectively. As a result, coal consumption decreased by 25.6% in FY2023 compared to FY2018 levels. Looking ahead, we will continue to promote reductions, and through capital investments of approximately ¥100 billion, project a downturn in GHG emissions of roughly 1,000 kt-CO2e.

In FY2023, we sold 1,631 GWh of electricity generated by biomass, hydropower, and solar power through the feed-in tariff (FIT) system for renewable energy under which electric utilities purchase electricity from renewable energy at a fixed price. This is equivalent to a reduction of 714 kt-CO2e in electricity consumer emissions.

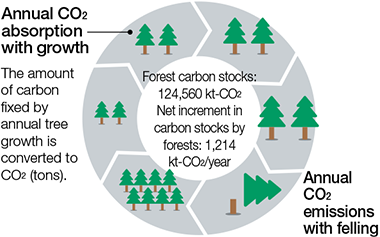

We are expanding the net increment in carbon stocks by forests by expanding plantations and planting fast-growing trees. In the 600,000 ha*1 of forests owned and managed by the Oji Group in Japan and overseas, actual carbon stocks reached 124,560 kt-CO2 at the end of FY2023, and the annual average net increment in carbon stocks by forests between FY2019 and FY2023 was 1,214 kt-CO2*2.

The amount of O2 released during the same period averaged 883 kt per year*3.

Forest carbon stocks: The CO2 stocks in Oji Forests

Net increment in carbon stocks by forests: The amount of CO2 absorbed by the trees in Oji Forests minus the amount of CO2 stored in the trees felled which are subtracted as emissions.

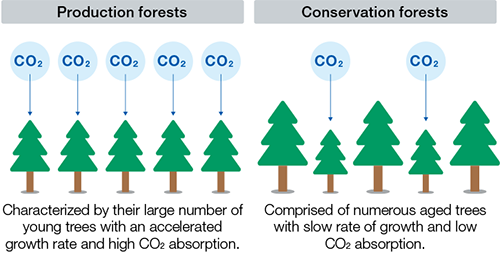

Recognizing that the amount of CO2 absorbed by trees is proportional to the amount of growth, production forests with abundant trees in a growth phase absorb more CO2 compared to conservation forests where trees have matured.

The Oji Group is expanding its overseas production forests and increasing the number of trees in a growth phase in a bid to increase the net increment in carbon stocks.

We expanded the area of overseas production forests from 237,000 ha as of the end of FY2018 to 275,000 ha*4 as of the end of FY2023. Moving forward, we are considering acquiring more sites for forest plantation primarily in South America, Oceania, and Southeast Asia, where we have been operating our forest plantation business. Our target is to expand the area of our overseas production forests to 400,000 ha by FY2030, at an estimated acquisition cost of about ¥100 billion.

CENIBRA in Brazil and KTH in Indonesia have long been breeding forest trees. In selecting and planting high-quality varieties, distinguished by their high growth rate and pulp productivity obtained through artificial pollination, efforts are being made to increase the amount of forest growth while facilitating carbon absorption and fixation.