The wood used for making paper is an excellent resource that can be reproduced through sustainable forest management. When managed and used appropriately, forest resources can contribute to the prevention of global warming (by absorbing and fixing carbon dioxide), the conservation of water resources, and the preservation of biodiversity.

In the management and use of forests, we ensure no deforestation and no illegal logging. We maintain and elevate our forest-related environmental values and at the same time we are aware that we must also fulfill our other social responsibilities such as respecting human rights and protecting labor and traditional rights in our forest operations. Based on this understanding, the Oji Group established its Wood Raw Material Procurement Guidelines as part of the Oji Group Sustainability Action Guidelines for Supply Chains to promote the responsible sourcing of wood raw materials from all wood chips and pulp suppliers who share our commitment to the guidelines.

Furthermore, amidst growing social concerns about human rights issues and deforestation, the Oji Group revised its Wood Raw Material Procurement Guidelines in March 2023 to respond to these social issues and continues to review them as necessary.

We also communicate the content of revised guidelines to suppliers around the world by making both Japanese and English language versions and disclosing them on our website.

The Oji Group requires and verifies that all suppliers produce sustainable wood raw materials. We will implement responsible procurement by surveying wood raw materials from all suppliers to ensure traceability and only purchasing materials from properly managed forests. If the source or forest management status of the purchased wood is unknown or the wood does not conform to the following, we will engage in dialogue with the supplier and request improvements. We will not source from suppliers who do not make improvements.

We will also utilize forest certification systems FSC™ or PEFC for verification. We will conduct the survey for imported wood chips on a per-ship basis. Domestic woodchips and pulp, which purchasing volume is smaller, will be surveyed once a year.

Under the guidelines for procurement of raw materials, we have established items to check the origin of raw materials, forest management methods, whether there is any illegal logging or mixed input of timber from high conservation value forests, and whether there is any infringement of human rights, among others.

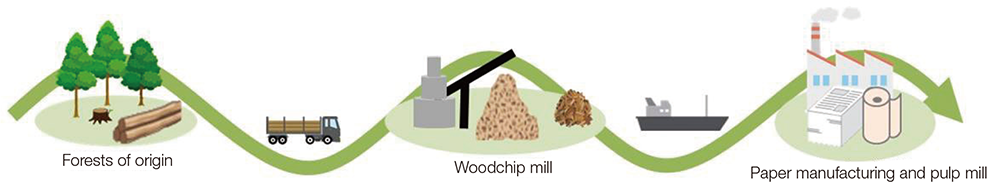

We procure only raw materials from properly managed forests, with a requirement to check for illegal logging, infringement of human rights, and other criteria. Furthermore, we can trace back the origin of wood materials through the entire process from the forest of origin to the chip mill to the pulp and paper mill.

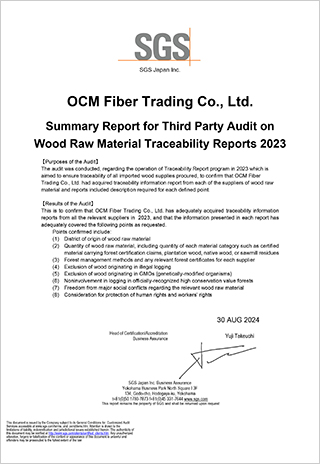

We monitor all suppliers of wood raw materials for compliance violations and disclose the results of our audits. In FY 2023, we procured 4,453 thousand BDT (dry weight tons) of domestic and overseas chips and 146 thousand ADT (wet weight tons) of purchased pulp, and we have received traceability reports (the response rate is 100%) from all suppliers (318 wood chip suppliers / 22 pulp suppliers inside and outside of Japan) to confirm that the procurement is in line with the procurement guidelines for wood raw materials by a third-party organization's audit.

We have representatives in major countries from which it imports wood chips. These representatives inspect shipments, advise suppliers regarding quality, and meet with them. When wood chips are loaded onto a ship, the origins of the raw materials, forest management methods, and other details are confirmed, and a traceability report is prepared. We verify that its suppliers maintain forest certifications, logging licenses, and records of round wood received.

As for domestic wood chips, we have representatives in major cities across Japan who meet with suppliers. The origins of raw materials, forest management methods, and other details are confirmed, and traceability reports are prepared regularly.

If we discover any non-compliance cases with standards such as forest certification or wood raw material procurement guidelines, we will communicate with the supplier and request improvements. We will not source from suppliers who do not make improvements. And we will provide relevant information and best practice examples for such suppliers so that "suppliers are aware of the requirements they must meet and work to comply with certification standards and relevant laws and regulations."

At Oji Group, we visit the mills and forests of our wood material suppliers every year. During these visits, we check the storage and records of essential documents such as logging permits, which form the foundation of our traceability reports. We also monitor compliance with our wood raw material procurement guidelines, focusing on human rights including workers' rights, safety and hygiene, and environmental considerations. These evaluations involve on-site inspections and interviews.

In 2023, we visited 45 of our 318 domestic and international chip suppliers to conduct these reviews. If we identify any violations or risks, we promptly request corrective actions and work together with the suppliers to resolve the issues.

Since 1985, CENIBRA has supported small-scale local farmers through its Forestry Development Program. This initiative helps farmers practice sustainable forest management by providing seedlings, fertilizers, and technical training. The program also guarantees the purchase of timber when it reaches maturity.

As of 2023, CENIBRA has ongoing contracts with 568 local farmers, covering a total of 18,159 hectares of plantation forests. About 15% of the wood materials delivered to CENIBRA's mill in 2023 came from these program participants. This long-term partnership has created jobs, raised incomes, improved living standards, and contributed to environmental conservation in the region.

CENIBRA has also implemented a satellite-based monitoring system to track the growth and management of contracted forests. This system ensures compliance with forest certification standards, such as preventing illegal logging and avoiding the conversion of natural ecosystems. Alerts from the monitoring system enable CENIBRA staff to conduct timely field visits and engage with suppliers, fostering effective communication and sustainable practices.

In March 2018, the Oji Group completed its registration as a Class-1 and Class-2 Registered Wood-Related Business Operator, which is stipulated in the Act on Promoting the Distribution and Use of Legally Harvested Wood (commonly known as the “Clean Wood Law”)*1 that came into force in May 2017. When we procure wood raw materials or biomass fuels in the future, we will verify the legality of the procurement by conducting due diligence to prove the legality*2 by working together with the Japan Paper Association.