The Group CEO Safety Award is granted to Oji Group’s all domestic and overseas worksites that meet certain criteria determined according to the business scale (number of employees) including the total work time without any occupational accidents resulting in temporary incapacity for work and the number of consecutive years without any occupational accidents. The Award is granted to worksites with outstanding records of no accidents together with the employees of those worksites and those of affiliates of Group companies with the aim of improving the safety and health levels of the Oji Group and eliminating occupational accidents.

In addition, the Oji Holdings Safety Administration Department conducts interviews and on-site inspections at workplaces that have been granted the Group CEO Safety Award. The department provides Group companies with information about such worksites as good case examples of safety activities as a measure for raising the overall Group’s safety awareness and improving its safety climate. We have also introduced the COMPANY President Safety Award and the President Safety Award at each Group company, and the Worksite Head Award as safety award programs, under which companies, worksites, and divisions with excellent safety performance are commended at each COMPANY and Group company.

Since 2020, we have gradually been conducting hands-on risk training sessions using VR at workplaces in Japan and overseas. Many participants remarked about the highly immersive VR video. One said, “In the disaster experience scene, I reflexively flinched or tried to run. The video let me experience accidents in a way not otherwise possible. I realized how scary accidents are and got a renewed sense of the importance of following rules.” Having produced original, experience-based content, including case studies that have occurred in the Oji Group, we exercised ingenuity in using 14 content scenarios so that students can learn not only in environments that are close to their day-to-day operations but also from fresh perspectives.

Oji Asia Packaging (OAP), which is supervised by the Industrial Materials COMPANY, has been playing a central role in meetings of safety and disaster control managers in Southeast Asia since 2016. Measures are undertaken with the aim of raising safety management levels at each company under the slogan“zero occupational accidents.” Personnel from Malaysia, Vietnam,Thailand, India, Cambodia, and Myanmar attend the meetings, where they inspect the worksite, receive explanations of the OAP safety promotion plan, review case studies of occupational accidents, and confirm important matters to be shared among the worksites through notices. The participants are eager to discuss safety initiatives.

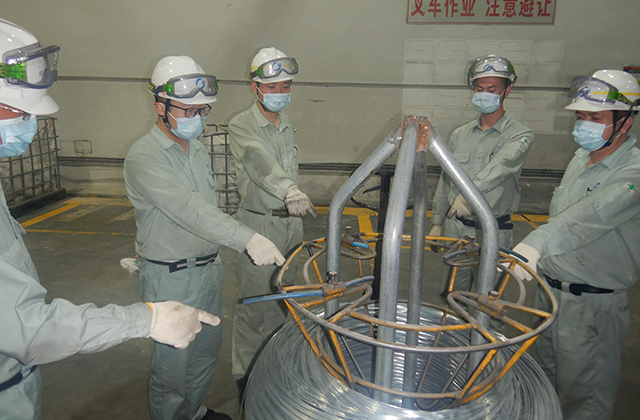

Since 2013, we have been holding the Plant Managers' Conference on the theme of safety and the environment, aiming to achieve "zero safety and environmental accidents" by deepening information exchange and interaction among plant managers and safety and environmental personnel. Attended by Oji Group companies in China, the conference includes site visits to the host plant, reports on Group initiatives by the Oji Holdings Safety Adiministration Department and Corporate Sustainability Department, presentations of the results of daily activities and good practices at each company, and a question-and-answer session.

Oji Group companies in China have been holding a Forklift Safety Workshop & Skills Competition since 2014. The events provide knowledge concerning forklifts and improve operating skills with the aim of achieving zero forklift accidents. During the forklift safety workshop, participants analyze the causes of forklift accidents, watch a safety video, and actively participate in a question and answer sessions, enhancing their awareness of safety.

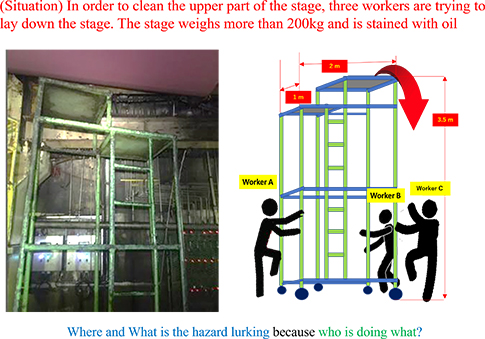

We are engaged in hazard prediction training (KYT) using KY sheets and case studies of accidents that have occurred in the Oji Group in order to increase the sensitivity of each employee to danger, to detect hidden risk factors in various conditions and situations, and to study various measures to improve sensitivity to danger and prevent accidents from occurring.

(Group companies in Southeast Asia under the control of Oji Asia Packaging of the Industrial Materials COMPANY: since 2020.

Group companies in China under the joint control of each COMPANY and Oji Paper Management (Shanghai) Co.: since 2021.)

Participants commented, "There are seeds of danger lurking in what we normally do without thinking," "There are seeds of danger that I am not aware of," and "I want to make use of them in my future work.”